Beretta A303 Shotgun Manual

05.10.2019 admin

Full text of ' Istruzioni per I'uso Instructions for operation Mode d'emploi ENGLISH Illustrations on pages 5, 34, 35, 36. Caution: read this manual carefully before handling and loading the gun. WARNING: Always ensure that the safety is fully engaged until ready to fire. A sa- fety is fully engaged only when the safety 'off' red marking (ring) is completely covered and when the safety can move no further into the safe position. The commandments of gun safety 1) Treat every gun with respect and caution. 2) Keep your eyes on the muzzle. Keep the safety on until ready to shoot.

Remington launched their iconic Model 1100 shotgun in 1963 – sparking a strong spirit of competition in Beretta, who determined to win some of their previous glory back. Two years later Beretta introduced the A300, the first of a collection of guns that continued to raise the bar and improve as the years rolled. Beretta carried on producing the popular A300 until the late 1970s, when the. Welcome to the Beretta Gun Parts section of Midwestgunworks.com. We carry parts for current production and post production Beretta firearms. Parts are available to the public for self installation, but can also be installed by our highly trained gunsmiths.

3) Unload guns when not in use; keep the actions open. 4) Be sure the barrel is clear of obstructions. 5) Be certain of the target at which you are going to fire. Know how to recognise the game you are hunting. 6) Never shoot at a flat surface or water. 7) Never climb a tree or fence or jump a ditch with a loaded gun.

Don't take a gun by the barrel. 8) Never point a gun at anything you don't want to shoot. Avoid all horseplay while handling a gun. 9) Store guns and ammunition separately, beyond the reach of children. Guns should always be unloaded. 10) Avoid alcoholic beverages before or during shooting. Shooting glasses and earplugs: shooting glasses are a must; chances of gas.

Gunpowder and dirt particle blow-back are remote but to exist. Earplugs reduce the chance of temporary or permanent loss of hearing when shooting.

Warning As the interchangeable barrel of the automatic has a different serial number to that stamped on the receiver, it may be necessary, when referring to the gun, to specify also the serial number of the barrel/s. 14 CONTENTS Page DESCRIPTION 16 a.

Packing 1 7 b. Main component parts 17 c. Assembly 18 d.

Loading 18 e. Use of the cut-off (optional device) 18 f. Unloading 19 g. Disassembly 19 h. Cleaning and Oiling 20 i. Magazine capacity 21 I. Reassembly 22 m.

Mobilchokes® 22 n. Drop Adjustement 23 15 DESCRIPTION The Beretta A 303 gas-operated automatic shotgun introduces some engineering and functional novelties: - The cut-off push button (optional device) is now placed in the lower part of the fore-end thus allowing an easier insertion and disconnection.The interchangeable choke (A 303 Mobilchoke' version) is now screwed directly inside the barrel: the traditional line of the gun is not altered and the choke to tube alignment is remarkably accurate.

The newly designed receiver shows a simple decoration and a new shape: the lower corners are now chamfered to allow an easier movement of index finger towards the trigger. The trigger guard is enlarged for a better look and a more practical winter use of the gun.

Stock and fore-end have been redesigned. The new A 303 automatic maintains all the basic mechanical characteristics of the A 302 model and the interchangeability of barrels with those of the previous models. The features and the advantages which have made the Beretta automatics famous all over the world are:. The possibility of utilizing Standard chamber (2 3/4 in.) barrels or Magnum chamber (3 in.) barrels on the same receiver. Rapidly interchangeable barrels to allow a large variety of barrel lenghts and chokes. The possibility of firing cartridges which range from minimum pressures up to 700 kg/cm 2, without any kind of adjustement. The very high accuracy and stability during fire ensured by a fixed barrel.

Extremely low recoil. Absence of vibration during firing due to the presence of the recoil spring inside the stock.

Reliable and safe cocking and firing mechanism. A special locking mechanism to ensure that the gun can fire only with the bolt completely engaged in the barrel. High durability of all components in contact with combustion gasses being made of either stainless or special steel. Easily adjustable stock drop.

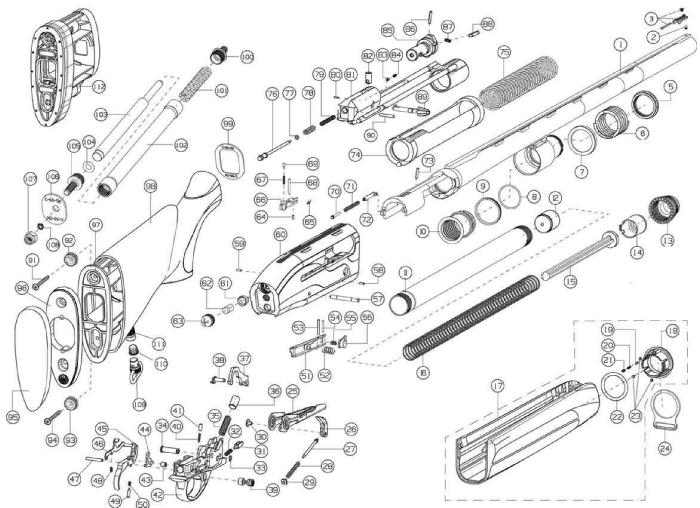

Easy field stripping for cleaning and inspection. Easy loading and unloading of magazine. Packing The Beretta series A 303 automatic shotguns are shipped from the factory with barrel taken down from the stock receiver fore-end assembly. Main components parts Before proceeding with the assembly of the barrel to the stock receiver fore- end assembly, study carefully illustrations 1 and 2 in which the main components parts are indicated and check them with the following nomenclature: A.

Feeding port A2. Safety button A8. Breech bolt A3. Trigger plate retaining pin A9. Cocking handle A4. Cartridge latch button A10. Extractor A5.

Ejection port A6. Carrier stop push button A12. Connecting rod BARREL B1. Gas cylinder B3. Barrel extensior B2. Cut-off push button (optional device) E.

MAGAZINE TUBE F. MAGAZINE TUBE CAP WITH SHAFT G. FORE-END CAP (with swivel) H. OPERATING ROD WITH SLEEVE N.B.: The barrel receiver for-end assembly is packed with the breech bolt A8 closed and hammer uncocked. If the breech-bolt is closed check the hammer is uncocked by pulling the trigger A1. — If, for any reason, the breech-bolt is open, close it operating as follows: Holding the cocking handle A9 with the index or middle finger of the left hand, press the cartridge latch button A4 and allow the breech-bolt to slide forward slowly until it stops (ill.

Unscrew (anticlockwise) and take off the fore-end cap G from the stock receiver fore-end assembly (ill. Slide fore-end D forward off magazine tube (ill. Slide piston B2 forward off magazine tube cap shaft (ill. Insert piston into gas cylinder B1 (ill. Pull the cocking handle A9 rearward to lock the breech bolt open (ill.

Insert barrel extension B3 into the receiver A, holding the barrel and gas cylinder with the right hand to prevent dropping the piston. During this operation take care that the magazine tube cap shaft F, enters the piston hole (ill. Force the barrel into the receiver as far as it will go (ill. Assemble fore-end over gas cylinder and magazine tube E (ill. Screw the for-end cap clockwise onto the magazine tube cap shaft which protrudes at the front end of the fore-end. Make sure it is screwed up tight.

Close the breech bolt by pushing the cartridge latch button A4, being careful not to get fingers caught in the ejection port A11 (ill. Whilst always taking care where the gun is pointing, even if unloaded, holding the breech bolt open about one centimetre, pull the trigger to uncock the hammer (ill. This makes for maximum safety by means of a visible check of the cartridge chamber to see if it is empty (ill. Loading (breech bolt closed) d1. Pull back cocking handle (see point c5). Push safety button A2 on SAFE position so that red marking disappears (which, when visible, indicates that the gun is ready to fire) (ill. N.B.: Gun goes on safety only when the hammer is cocked.

Through the ejection port insert the first shell into the chamber (ill. Close the breech bolt (see point c10). Raising the carrier A5 with the shell itself, insert a further two shells into the magazine through the feeding port A7 until they snap on the shell latch (ill. The shotgun is now ready for use. In order to fire put safety off. C Use Of the CUt-Off (loaded shotgun with chambered shell) The cut-off D1 makes it possible to lock the breech bolt open to replace the chambered shell while interrupting at the same time the shell feed from the magazine. Put safety on SAFE position (see point d2).

Holding the gun with the left hand, pull completely back the breech bolt operating on the cocking handle with the index finger of the right hand. Then, keeping pressed the cut-off push button (push on the PB marked part) with the index finger of the left hand, shortly release the breech bolt until it stops in the open position and remove finger from the cut-off. During the rearward movement of the breech bolt the chambered and unfired shell is extracted and ejected through the ejection port (ill. Insert another shell (of your choice) into the chamber. Keeping fingers away from the ejection port, push the cut-off button (push on the front hollow part) in order to disinsert the cut-off itself and let the breech bolt close rapidly (ill. The gun is now ready for use. In order to fire put the safety off.

N.B.: If the shotgun is to function properly, it is recommended that the cut- off is used as described above. In particular it must be remembered that the breech bolt - when held open by the cut-oft - can be closed only operating on the cut-off lever itself.

Unloading (gun supplied with cut-off) ft. Follow the instructions given in points e1, e2, e4. Whilst pushing in the carrier and pressing in at the same time the cartridge latch button in the direction of the shotgun's stock, allow the shells to come gently out of the magazine (ill. Put safety off and operate as described in point ©II. (gun without cut-off device) f4.

Put safety on SAFE position (see point d2) f5. Whilst always taking care where the gun is pointing, even if unloaded, pull back the breech bolt in order to extract the unfired shell from the chamber and eject it through the ejection port. Remember that the breech bolt does not remain locked in the open position. Quickly release the cocking handle and let the breech bolt close rapidly. Repeat operation described at point f2 (fig. Make sure magazine tube is empty and follow operation described at point c11 with safety off.

Disassembly BARREL g1. Make sure that the gun is unloaded (chamber empty, magazine tube empty). If it is not unloaded, unload the gun following the instructions given in points If, f2, f3, when the gun is supplied with the cut-off optional device. If weapon is not supplied with the cut-off device, follow instructions given in points f4, f5, f6, f7. Pull back the breech bolt (see point c5). Put the safety on (see point d2). Unscrew (anticlockwise) and remove the fore-end cap.

Slide the fore-end forward off magazine tube. Grasping the barrel at the height of the gas cylinder, hold the piston inside the gas cylinder with the right thumb to prevent dropping it; slide barrel assembly forward off stock-receiver-fore-end assembly (ill.

BREECH BOLT g7. Holding the cocking handle with the index or middle finger of the left hand, press the cartridge latch button and allow the breech bolt to slide slowly to a rest (ill. Remove the cocking handle with a jerk (ill. Hold the stock receiver assembly on a flat surface, with the feeding port facing upward, with the left hand; with the right hand grasp the operating rod H and slide it forward off the magazine tube to detach the breech bolt assembly from the receiver (ill.

The breech bolt assembly no longer held by the action bar will divide into its two main components (ill. breech bolt slide with connecting rod and pin - breech bolt assembly, locking block, firing pin extractor. TRIGGER PLATE g11. Press in carrier stop push-button A6 (ill.

Detach the trigger plate retaining pin A3 by pressing with the point of a drift or some other pointed object (ill. Keeping the cartridge latch button pressed, slide the trigger plate forward and downwards (ill.

It is not advisable to carry out any further disassembly of the shotgun. If any should be necessary it should be entrusted to a competent gunsmith. Cleaning and oiling BARREL - After some use carefully clean the inside of the barrel by passing a soft cloth (flannel) through the barrel in order to remove combustion residues.

Pass another clean soft cloth through the barrel. Oil it lightly by passing a clean soft cloth soaked with Beretta oil or an equivalent through the barrel. GAS CYLINDER - PISTON WITH BUSH - MAGAZINE TUBE CAP SHAFT - At the end of the hunting season and always before storing the gun for a 20 quite long time, it is necessary to clean carefully the above mentioned parts, spraying them liberally with Beretta detergent or an equivalent. Give the detergent a few minutes to take effect, remove then the detergent and all the combustion gas residues with a phosphorous bronze brush and with a cloth soaked with detergent. Dry the parts carefully with a soft cloth. N.B.: There is no need to oil these parts. BREECH BOLT - Every 500/800 shots clean the component parts carefully with a small brush and Beretta detergent or an equivalent.

Dry carefully with a soft cloth and lightly oil the parts with Beretta oil or an equivalent. TRIGGER PLATE - Follow instructions as given for the breech bolt. INSIDE OF RECEIVER - Follow the same instructions as given for cleaning the breech bolt. Lightly oil the bolt slideways with Beretta oil or an equivalent. OUTSIDE OF MAGAZINE TUBE - Clean using Beretta detergent or an equivalent and soft cloth. Lightly oil the tube with Beretta oil or an equivalent.

Magazine capacity The capacity of the A303 magazine tube (which hold three shells) is limited, in observance of the hunting regulations in force both in Italy and other countries, to two shells by a shortening device called a reducer. This reducer limits the use of the A303 to three shells (two in the magazine and one in the chamber). Beretta includes the reducer in the A303 directly in the factory.

In some areas only hunting with shotguns with a capacity of two shells is permitted. To be able to use the A303 in such areas it is necessary to limit the capacity of the magazine tube to just one shell. Such an operation should only be carried out by a competent gunsmith.

Beretta A303 Parts

For use in countries where hunting with shotguns with a capacity of more than three shells is permitted, it is possible to increase the magazine tube capacity to three shells. Again this operation should be entrusted to a competent gunsmith.

To reduce the capacity of the magazine tube: i1. Unscrew (anticlockwise) the magazine tube cap with its shaft, at first keeping pressed in with a sharp point the head of the locking spring of the cap itself (ill. N.B.: Pay attention with the magazine spring which will be compressed (it rests against the reducer, coloured yellow).

Beretta A303 20 Gauge

Insert the second reducer into the first (the solid part into the hollow part) (ill. Screw (clockwise) the magazine tube cap onto the magazine tube, making sure that the head of the locking spring is inserted into the right hole, that is, blocking the cap. In order to increase the capacity of the magazine to three shells, simply take out the reducer/s. Reassembly TRIGGER PLATE 11. Carry out in reverse order the instructions given in point g13, making sure that the hammer is cocked and the carrier stop push-button is pressed in. Insert the trigger plate retaining pin taking care that the hole of the trigger plate is perfectly aligned with that of the receiver. BREECH BOLT 13.

Reassemble the breech bolt assembly by fixing the breech bolt slide with connecting rod to the breech bolt body (ill. Insert the rear of the operating rod into its slot on the breech bolt (ill. Press in the carrier stop push-button (if not already pressed). Holding the receiver on a flat surface with the ejection port facing upwards, slide the operating rod sleeve onto the magazine tube and partially insert the breech bolt assembly into the receiver (ill. Holding the stock-receiver assembly absolutely vertical, slide the operating rod sleeve downwards compressing the recoil spring, until the breech bolt remains fixed in an open position (ill. N.B.: If the operation, described in point 17, is to be carried out with ease the head of the breech bolt connecting rod must slide into its recoil spring guide slot. This will occur only if the rod is exactly coaxial to the breech bolt assembly and centered properly in the cocking handle slideway.

Insert the cocking handle in the breech bolt. Follow the instructions given in points c6, c7. C8, c9, c10, c11.

Mobilchokes' (A 303 Mobiichoke.) REPLACEMENT, CLEANING ml, Unscrew the choke anticlockwise, using the multiple spanner included (ill. Clean perfectly the choke chamber.

If necessary, use Beretta detergent and a brush. Dry carefully with a soft cloth. Should, after long use, the internal screw thread need to be cleaned, carefully screw inside the barrel the threaded head of the multiple spanner supplied, paying special attention not to damage the barrel thread. Fit the desired choke in the barrel, checking it is perfectly clean. Screw on clockwise the choke and tighten it to the end with the multiple spanner. N.B.: Check while hunting wheter the choke has in any way become loose.

Should this happen, the choke must be tightened to the end again. Be sure, before operating that barrel chamber and magazine are empty. WARNING: Remember that the use of the barrel without choke inserted is not allowed. Should this happen, the internal screw thread could be damaged. Drop adjustment The Beretta automatic is packed with drops varying from 45 to 65 mm., depending on models and circumstances. To adjust the drop there are special metal spacers numbered according to the drop desired, and are used as indicated in the following diagram and as per ill. DROP ADJUSTMENT DROP mm.

45 50 55 60 65 1. DROP 0,5 1 2.

Adjust in B C 3. Fit the required metal spacer into the butt.

23 35 STROZZATURE/CHOKES F 1/1 00 IM 3/4 000 M 1/2 0000 IC 1/4 coooo C 0/0 S (Skeet) S SK SB (Skeet Beretta) 36 NOTE NOTES Le illuslrazioni e descrizioni di qucsto opuscolo si Intendono lornite a lilolo indicative La Casa $1 riserva pertanto II diritto dl apporlaro ai suoi modolli. In qualsiasi momenlo sonza proawiso. Quollo modlllcho cho tilonosso utill por migllorarll o por qualsiasi esigenza dl dl carattoro costrulllvo o commerciale. The lllusltallons and descriplions given in this brochure aro intended as a general guide only, and must not be taken as binding. Reserves the right to make, al any moment and without nollcc. Any changes It thinks necessary to improve its models or to meet any requirements ol manufacturing or commercial nature.

Les illustrations el tos descriptions conlenues dans co prospectus ne sont donnees qu a litre indicatil. La Maison se reserve le droit do modllier. A tout moment el sans preavis, ses modetes pour les ameliorer ou pour nimporte quelle exigence do caractere constructs ot commercial Boretla Pubblicita.

cod 60646 5/95 (5) Printed in Italy batan. Beretta A TRADITION OF EXCELLENCE SINCE 1526 Fabbrica d'Armi Pietro Beretta S.p.A.

Via Pietro Beretta, 18 - 25063 GARDONE VAL TROMPIA (Brescia) Italia Tel. (030) 8341.1 - Telex 301523 PB BS I - Fax (030) 8341.421.